The Future of Ceramic Coatings: Advanced Nanotechnology

Keeping surfaces looking pristine is an ongoing battle against time and elements—especially when it comes to cars subjected to daily wear and tear. Traditional protective layers, while helpful, often require constant upkeep. Fortunately, advances in nanotechnology have led to the development of ceramic coatings that boast not only superior durability but also remarkable protection.

What Are Ceramic Coatings?

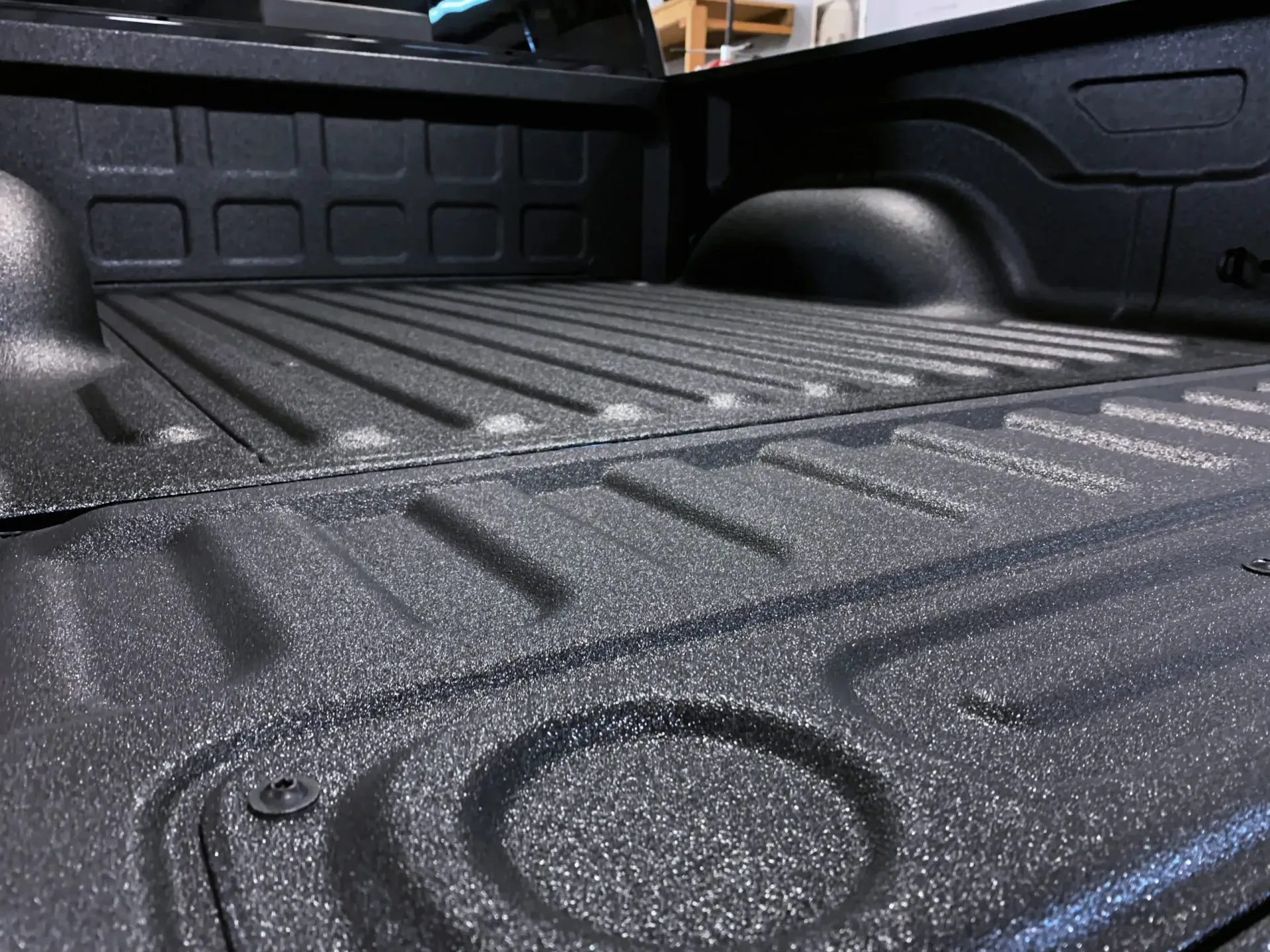

At their core, ceramic coatings provide a unique form of protection by utilizing advanced materials that create a robust barrier between the surface and the environment. These coatings are primarily composed of silica. When applied, they transform into a solid layer with impressive durability. This transformation occurs as the liquid coating cures and forms a glass-like finish, making it not only aesthetically pleasing but incredibly functional. The result is a surface that stands up to harsh weather conditions, UV rays, and chemical exposure.

One of the most amazing qualities of ceramic coatings is their ability to repel water. These coatings provide a hydrophobic effect on the outside of cars, which makes water bead up and roll off easily. Because dirt and grime have a harder difficulty clinging to the surface, fewer washes are needed as a result. Imagine yourself driving through a downpour and the water just sliding off your car without leaving any stains or streaks behind!

Benefits of Ceramic Coatings

The appeal of ceramic coatings lies in their numerous advantages over traditional waxes and sealants, paving the way for a revolution in surface protection.

Enhanced Durability

First and foremost, enhanced durability is one of the most compelling reasons to consider this technology. Ceramic coatings provide an impressive level of resistance and can last up to five years with proper upkeep, significantly outperforming standard waxes that typically demand reapplication every few months. This long-lasting nature reduces the frequency and cost of upkeep, making it a smart investment for vehicle owners.

Protection Against Environmental Damage

Beyond their durability, ceramic coatings serve as an impenetrable barrier against environmental damage. They protect your vehicle from harmful elements like UV rays, acid rain, salt deposits, bird droppings, and various pollutants that can mar its exterior. These coatings are engineered to withstand harsh conditions and maintain their integrity over time.

According to research, vehicles treated with ceramic coatings exhibit a remarkable 50% less paint degradation compared to non-coated vehicles over a three-year period. This statistic alone underscores why avid car enthusiasts are embracing this innovative technology.

Ease of Maintenance

Water and grime are less likely to cling to the surface, meaning your car appears cleaner for longer periods. Users often report spending half the time washing their vehicles compared to when they relied on traditional products.

This time-saving attribute is not just about convenience; it fosters an alluring appearance that stands out significantly against untreated surfaces. By reducing the frequency of washes required while improving the overall look, ceramic coatings create more time for enjoyable activities or simply relaxing.

Role of Nanotechnology in Enhancing Coatings

Nanotechnology plays a pivotal role in elevating the performance of ceramic coatings, significantly advancing surface durability and resilience. By manipulating materials at the nanoscale—typically between 1 and 100 nanometers—manufacturers create coatings that bond with surfaces on a molecular level. This not only increases adhesion but also enhances the overall strength of the layers applied. As a result, the coatings exhibit improved resistance to scuffs and chemical damage, ensuring long-lasting protection.

At this microscopic scale, nano-sized particles are specifically engineered to fill in the minuscule gaps found in a surface. Imagine it as tailoring a suit: rather than draping an oversized garment over a body, tailored fabric hugs every contour snugly. Similarly, these tiny particles smooth out imperfections and create a more uniform coating. This enhanced consistency minimizes surface porosity by up to 70%, creating a denser barrier against environmental factors like moisture, dirt, and UV rays.

As this protective layer becomes more resilient through nanoparticle incorporation, it also adapts to changes in temperature and stress. For instance, many formulations can withstand thermal stability exceeding 1000°C, a crucial attribute for high-heat applications.

Application Process and Effectiveness

The secret to achieving durable and aesthetically pleasing results lies within a well-defined application process. It might seem straightforward, but each step is vital and impacts the overall effectiveness of the ceramic coating. The first crucial action is to thoroughly wash and decontaminate the surface. This means removing any dirt, grime, or existing wax that could inhibit adhesion. Think of it as preparing the canvas before painting; any flaws on this surface will ultimately show through the intended finish.

Once the surface has been properly cleaned, you're ready for the next step: ensuring it’s smooth and flawless.

If your vehicle's paint exhibits imperfections like swirl marks or surface wear, conducting a paint correction becomes necessary. This process uses abrasive compounds to achieve a glass-like finish that allows the ceramic coating to adhere correctly. Skipping this step could prevent the coating from performing its best, leading to subpar results. Remember, a smooth surface enhances both aesthetic appeal and functional durability.

After preparing the surface, it’s time for the exciting part: applying the ceramic coating. When it comes to applying the actual ceramic coating, an applicator pad is essential; small, controlled sections should be your mantra here. Using too much product or attempting to cover large areas can lead to unevenness or streaks. Instead, work slowly and methodically—this ensures that each inch of your vehicle receives an even layer of coverage. It's not just about slapping on a coat; quality over quantity is key if you want that pristine glossy finish that makes your reflection look sharp and clear.

Recent Innovations in Ceramic Coatings

One of the most exciting advancements in ceramic coatings is the introduction of graphene-infused ceramic coatings. Graphene, a single layer of carbon atoms arranged in a two-dimensional lattice, has gained attention for its exceptional strength and conductivity. By incorporating graphene into ceramic coatings, manufacturers have enhanced several key properties that were once thought to be at their peak with traditional materials.

These graphene-infused coatings offer durability while also improving thermal conductivity, making them ideal for high-temperature applications. Test results have shown that these innovative coatings can withstand temperatures substantially higher than what standard ceramic coatings can handle.

Get a Flawless Finish with Ceramic Coating at The Works Auto Center

Ready to protect your vehicle and give it a pristine glossy shine? At The Works Auto Center, our expert ceramic coating application ensures that your car is safeguarded against UV rays, contaminants, and environmental damage. Experience enhanced durability, superior shine, and cutting-edge innovations like graphene-infused coatings.

Schedule your ceramic coating service today and keep your vehicle looking its best for years to come!